Posted to Technical Discussion Forum on 6/25/2011

65 Replies

Hi all. I have followed with interest some of the posts in

the last year or so, where CAN based communication case

studies have been presented for our interest and discussion.

In particular, more recently James Avery posted a High Speed

GM LAN issue and as I observed the ensuing thread unfold, it

became apparent that there was plenty of interest in this

topic.

While CAN systems have been around for a long time, we have

seen CAN "C" brought into the forefront since the 2008 MY.

What I notice is that the case studies are great, but

participation is somewhat limited to a few "die hards" who

either understand the system function, failure and

diagnostics, or conversely, quite openly admit that they

lack knowledge of the CAN systems and yearn for more.

So, the purpose of my post is to contribute some numbers and

a few thoughts to the cause. While I no longer actively

wrench as a technician, I must also learn each new

technology and system as it is introduced, on a wider range

of vehicle systems than when I was a technician full-time.

Apprenticeship, vehicle manufacturer and dealership needs of

the shop and technicians, dictate that we train students in

specific areas and network communications is a clearly

defined apprenticeship topic in third level.

While my work may not quite assimilate your "real world"

experiences, it is my "real world", where not only installed

bugs, mishaps, damage and other problems happen to challenge

us along the way. During my week, there is some time set

aside without students present, for me to attend to

"Functions 3 to 8" in our collective agreement. This covers

a wide range of program maintenance needs, processing marks,

prepping labs and taking care of ensuring that everything is

up and running.

This particular Friday began with me scheduling marks

processing and prep work, but first I needed to move a few

vehicles around for the next series of activities. One car,

a 2009 Chevrolet Mailbu 2.4L, was sitting in the shop. That

needed to go outside, but it didn't crank. The dome lamps

and IP were lit with doors open and key on, exterior lamps

turned on, but nothing happend when the key was turned to

crank. Without getting sidetracked, there were a few other

systems that didn't function, such as the electric trunk

release, but all that I wanted at this point was to shift

the beast outside. I'm on my own, all alone with nobody with

me, so pushing is out.

Darn, I'd better fix it myself, methinks. Besides, this is a

bit more interesting than paperwork anyway. Work boots, and

PPE at the ready, what's the next step going to be? I know

where iATN's resident litigation consultant would have us

head, word by word, but GM created something known as

"Diagnostic Strategies" a few years ago, that provides GM

technicians with more diagnostic freedom to use their

knowledge, expertise and experience to either use some very

basic methods, or if a novice, to do the step by step dance.

I manage my novices closely enough to develop and install

some critical thinking skills and to understand that they

need to be able to manage their diagnostic skills and logic

within reasonable relams of the corporate process to be sure

to be paid. Once they have developed a wider range of

skills, their wings will be set free to soar, but for now

they're "clipped" to keep them from wandering too far from

the beaten path. Since I routinely lead students into

developing a logical diagnostic approach that may

assimilate, but not necessarily 100% duplicate the

manufacturer steps, based on needs and critical thinking

abilities, much of the stuff is ingrained in my "noggin."

Besides, I'm not on flat rate any longer and I am my only

audience, with the freedom to stray, wander and experiment

today, as I see fit.

So, let's gather a little info. What do I know of the

vehicle? It is a 2009 Malibu, donated to the program by GM

Canada, with a couple of scrapes/mild dents in the roof from

transit damage. It has performed flawlessly to date, used

for various topics this term from body electrical, network

communications, engine management and emissions. I don't

know and really don't care at this point, how it became

non-functional. I'm just a tech today with a broken car in

my work bay that needs to be fixed ASAP.

Now, you already know that as I write this, that the vehicle

may well be fixed and it is, but when I spent a minute or so

getting my diagnostic direction figured, it became apparent

that this may be useful in a post. To that end, I elected to

snap a few photos of scan data, DMM display values etc along

the way. Since taking photos of a DMM display with overhead

lights, trouble lights and other effect on camera angle, can

produce inconsistent quality photos, I snapped some photos

of the Fluke 87 V photo, but for clarity, created some text

boxes for better viewing on this wet Saturday afternoon.

So, what's the approach? Preliminaries, looked okayish and

while I might have tested every fuse in some random fashion

like many do, which simply wastes time, I'd rather home in

on what's working or not working in the major sense, to get

a better grasp. Besides, if get a schematic, it will show

the appropriate fuses and save a bunch of time not checking

those that don't need it.

While a few other things may or may not work, my primary

concern was a no crank, no click, no nothing response to

rotating the ignition key. Keep in mind, preliminaries

include visual, bulletins and more, depending on need, so

I'll keep that in mind. In my ex-role as a GM technician,

I'd use my "gut" feeling diagnostic approach to gain a sense

of direction, willing to trade 5 minutes or so using what I

know, versus following the "path of righteousness". No sense

of where to go, get on track with published info, not much

time lost.

Anyway, I know where the Diagnostic Starting Point et al,

will lead, so don't need to read it for the ten thousandth

time just yet. So, with Tech 2 and CANdi in hand, vehicle

info entered, the results of selecting "Vehicle Control

Systems" and waiting what seems like an eternity, renders

some modules with no communications and some with DTCs, on

Low Speed and High Speed GM LANs (HS & LS).

Ah, the path to take. Info is readily captured and kept in

mind for future needs. All this happened at one instant in

time, so in my mind, one problem is likely presenting

multiple DTCs and symptoms. I note that the BCM (on LS and

HS LAN) is present and showing 3 DTCs U2105 00, U 2106 00

and U2108 00, all were communication lost with other module

DTCs. There's also U 2109 00 (PSCM) and B2455 04 (VCIM)

listed.

So, we have problems communicating with various modules and

since the BCM and VCIM reside on both HS and LS LANs, some

stuff that may be useful later. Go ahead if you wish, check

bulletins and find the one that lists four of the five DTCs

and jump to conclusions that will not net a successful

diagnosis. I just log this stuff into long term memory in

case actual diagnostics don't yield a fix.

Now, I am already well aware from my background and

training, of the fact that some" big player" modules that

some of the DTCs represent only communicate on the HS LAN,

while some of the lower priority modules reside on the LS

LAN. Now, "Diagnostic Tragedies" as we so fondly call it,

allows us some freedom, but for those of you unfamiliar with

GM LAN schematics, you can use the menu path or a keyword

search to seek out some visual aids.

I didn't need to take this path, because I'm already homing

in on the HS LAN to do some basic tests, but then again, I'm

familiar enough to go ahead at this point. Still, looking at

the schematics can render some useful information such as

where to access the system for diagnostic tests beyond the

DLC.

Using the menu file path, head over to Power and Signal

Distribution, Data Communications, Schematics and Routing

Diagrams, Data Schematics, to arrive at Power, Ground and

Serial Data, where HS LAN is available with or without HP7

(hybrid) and LS LAN is also listed. This one is not equipped

with HP7. A quick review of both LAN schematics and noting

connector locations may be useful while here. Clicking on

the "LOC" button on a schematic (not available once in the

magnified view), will net the Master Electrical Component

page, where all components, connectors and harness routing

diagrams should be located.

If you want to have both windows, when clicking on the LOC

button, use the right click, open in a new window " method.

Real world, I rarely would bother. If I have an interesting

window open, I print it and take it to the vehicle.

If I already know the connector ID, I don't waste time with

file paths. Keywording "Master" from any search box and

dragging the slider rapidly to the very bottom of the page

will net "Master Electrical Component List" at or just above

the very bottom. The path above is for you if you wish, but

based on my knowledge, I'm going to do some quick tests at

the DLC.

Since the BCM is online, but nothing else, I expect that

voltages on the HS LAN should be as expected. I did make one

notation when I used the schematic, to aid my testing and

that was the location of the two 120 ohm termination

resistors in the HS LAN circuit. One is in the BCM which is

one stop downstream from the DLC and the second is internal

to the ECM, which is at the far end of the system, not

communicating.

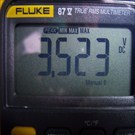

This is the value obtained [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing]

That makes me happy, since if the resistance is as I

expected for a system with a data line problem that I

predicted from scan data and system funcitonality, I'm

probably looking for a simple open in the circuit. Don't

forget though, any time you make resistance measurements,

the system should be powered down for the values to make

sense. I caught a couple of students last week, diagnosing

an '08 Aveo CKP failure, measuring a ground circuit with the

ignition on, DRL (headlamps) shining brightly. They were

wondering while their measure valued was a really high ohms

value, but did net the same result on another ground. I just

happened to beat them to the ignition switch! VBG.

To get a mental picture, this HS LAN begins with the DLC and

strings modules along one after another and culminates at

the ECM. Two wires (Bus + and Bus -) enter and leave each

module. Looking at the schematics with the choices of RPO

applications can give you a headache and a couple of modules

are hung off the side of the chain and also have LS LAN

communications. If you need, it can be simpler to draw a

block diagram.

In this case I suspected that I would find around 120ohms

resistance when I measure the HS LAN across Bus Hi and Bus

Lo terminals 6 and 14 and net 121 ohms. If functioning as

designed, the value should be close to 60 ohms Don't forget

though, modules/networks need three things to function,

power, ground and a healthy data line. I have a scan tool

that functions, BCM is active and my focus is on physical HS

LAN Data Bus wiring.

Nothing beyond the BCM is communicating on the HS LAN. The

BCM is "conveniently" located in the centre console, where

each side panel is released by gently pulling to release the

fastener clips and Velcro. Access is pretty simple. I don't

look too deeply, but the BCM connections appear to not have

been disturbed by student hands, wiring all seems to be in

place securely.

Next stop along the trail is connector X206, sorry forgot to

snap a pic of these locations. It is very conveniently

located behind the removable access panel at the left end of

the dash, with the driver's door opened. Yippee, pick me,

pick me, I found it, stumbled right onto a problem!!! There

is a lever lock style connector that also has locking tabs,

but it is not fully seated. I'm not so sure that the

terminals can even make connection properly unless the lever

mechanism is snapped home, but I'm a "happy camper" (or will

be if this is the only thing I find wrong). I'll investigate

later whether this is a student installed bug or whatever,

but for now, I just want the vehicle out of the shop, so

that I can complete some paperwork and prep for next week.

With the ignition off, I pull the connector halves apart and

inspect for anything that might prevent them from proper

intercourse and find nothing. All terminals of this hybrid

(two sizes of terminals in one connector body) are fine and

undamaged. With the connector reconnected, the engine now

cranks and runs fine.

So, since I mentioned that I'd record some HS LAN

measurements for reference, I will disclose the values

measured from the DLC, prior to me chasing down the open

circuit. When testing the HS LAN, there are some very basic

tests to be completed and not all are necessary to complete

the diagnosis (See Diagnostic Strategies) if the fault is

found. The status of the HS LAN can be checked using a DMM

or a DSO if you so wish, but it needs to be fast enough to

capture the data accurately enough for comparison to specs.

Throw away that cheapo $25 meter and ante up for a

professional DMM. GM recommends the Fluke 87 V and since I

have one, I used it to record the following measurements. I

did also use a Fluke 87 III, which while a capable meter and

did capture reasonably accurate results, was just a skip

behind the 87 and I did have to retake a couple of

measurements. I noticed that the high and low values on peak

min max were not quite as high or low when using the 87 III,

but they were still valid enough to make sense.

What's to be measured? Well, the simplest is to check the

resistance across HS LAN terminals 6 and 14 at the DLC.

Here's the measurement after the system has been repaired

[2009 Chevrolet Malibu LS, ECM/Inputs/Outputs Photo]

On a healthy HS LAN, this should be approximately 60 ohms,

but on a system where the module with the second terminating

resistor is missing, 120 ohms will be measured if the data

Bus is open. Remember, we still need power, ground, a

healthy pair of data lines and modules for everything to

function normally.

Here is the resistance check value again, of this Malibu

with no communication on the HS LAN data lines beyond the

BCM. [2009 Chevrolet Malibu LS, ECM/Inputs/Outputs

Drawing]

Additionally, there is a photo of the external termination

resistor from a current model GMT900 Chevy/GMC pickup truck,

showing the same value as achieved on the Malibu. [2008

Chevrolet Silverado 1500 LT, ECM/Inputs/Outputs Photo]

This resistor resides on the left frame rail close to the

spare tire.

The resistors provide a load on the circuit and also are

very useful diagnostic aids as James, Bob and others have

already eluded. I would suggest that if you wish to learn a

little about GM HS LAN diagnosis, that these trucks are

plentiful and easy to access. I'll let you be creative and

learn for yourself, what happens when you remove this

resistor and leave the circuit open or jumper the lines

together, or ground either one or both. This is your

homework project! You will learn when you do it for

yourself.

Measure voltage using a high quality meter capable of making

the following measurements: Measure terminals 6 (Bus Hi) to

(5 Ground) with a DMM on volts. [2009 Chevrolet Malibu

LS, ECM/Inputs/Outputs Photo] Note the measurement is in

basic DC volts and also autoranging. it was simply turned on

with voltage selected set up to make basic voltage

measurements, but regardless of whether a fixed range is

selected the meter just isn't fast enough for testing serial

data communication circuits accurately this way.

You can try the Fluke 87 variants on min max, where the

meter is not auto ranging, but will need to depress the

"speaker" button to select Peak Min Max for the reading to

be accurate enough. Since the 87 V is four times faster at

250 microseconds in peak min max, as opposed to the 87 III

mS capability, I'm going to use the 87 V for these

measurements.

What do we know about the GM LAN? It utilizes a twisted pair

of data communication lines aka Data Busses. They are

stacked at the DLC at terminals 6 and 14, which are directly

above and below one another, since its hard to have twisted

pairs anyplace but next to one another. Here's the DLC

terminal pin assignment [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Photo]

HS is at terminal #6 and the wire is tan with a brown

tracer. LS is at terminal 14 and the wire is tan in colour.

When we make measurements from terminal 6 to 5 (ground), we

expect to find a nominal 2.5 volts when measured on a DCV

scale. In reality, the value for terminal 6 will be a few

points of a volt higher than for terminal 14. Remember, this

is when performing a basic voltage measurement.

When we select the peak min max function, the values will be

quite different. E.g. we should see approximately 3.5V MAX

measured at 6 to 5 and 2.4v MIN. This verifies our

understanding that HS Bus HI moves up approximately 1 volt

during activity.

Similarly, when making the same peak min max measurements

from terminal 14 - 5, we will see approximately 2.5v MAX and

1.5v MIN values displayed if all is well, with the same 1

volt differential from rest. If voltages do not fall into

these ranges, problems exist that require diagnosis, such as

any short to voltage, open or ground condition will cause.

When measuring voltage across terminals 6-14, we will

measure somewhere in the millivolt range between 50 and 500

millivolts. This one measured [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing]

However, when we repeat the same measurements using the peak

min max feature of the Fluke 87 V, the results will be in

the neighbourhood of 2.4V MAX and 0.25V MIN. Here are the

actual measurements [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing] and [55184] This reading is

simply the differential voltage on BUS and the only way to

see it is using a meter or scope that is capable of

recording accurately.

I happened to have a couple of logic probes handy along with

a few other "quick and dirty" tools for basic system quick

checks, but prefer the peak min max on the DMM because the

numbers mean more to me. "Scopeaholics" can capture very

accurate waveforms and analyze them to "death." Personally,

I use the "KISS" approach when diagnosing vehicles and use

the most basic tools first. If I am not satisfied or looking

for something beyond, I have scopes close by for back up.

Bear in mind that some vehicles utilize more than one HS

LAN, simply to limitations of the CAN BUS. In those cases,

we might find a chassis expansion bus or hybrid expansion

bus, piggy-backed to the system, much like you can add an

electrical subpanel to your home electrical system.

So, when James and other post voltages, we need to

understand or at least ask how the measurement was made, if

we are to be able to compare their measurements to good

known values. If the method of recording the voltages isn't

good enough, the numbers won't provide proper diagnostic

value.

Here are actual photos and a series of text boxes showing

Volts and Ohms Basic tests follow:

KOEO Terminal 6-5 = [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Photo]

KOEO Terminal 6-5 peak min max -- MIN = [2009 Chevrolet

Malibu LS, ECM/Inputs/Outputs Drawing] KOEO Terminal 6-5

peak min max - MAX = [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing]

KOEO Terminal 14-5 = [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing] KOEO Terminal 14-5 peak min

max -- MAX = [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing] KOEO Terminal 14-5 peak min

max -- MIN = [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing]

KOEO Terminal 6-14 = 0.314v DC [2009 Chevrolet Malibu

LS, ECM/Inputs/Outputs Drawing] KOEO Terminal 6-14 peak

min max- MAX = [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing] KOEO Terminal 6-14 peak min

max -- MIN = [2009 Chevrolet Malibu LS,

ECM/Inputs/Outputs Drawing]

Powered down Terminal 6-14 ohms ( in spec) = [2009

Chevrolet Malibu LS, ECM/Inputs/Outputs Drawing] Powered

down Terminal 6-14 ohms (out of spec) = [2009 Chevrolet

Malibu LS, ECM/Inputs/Outputs Drawing]

Here's a few of the other Fluke 87 V photos. {File55169]

[2009 Chevrolet Malibu LS, ECM/Inputs/Outputs Photo]

[2009 Chevrolet Malibu LS, ECM/Inputs/Outputs Photo]

[2009 Chevrolet Malibu LS, ECM/Inputs/Outputs Photo]

The basics of the GM HS LAN is that at rest, the voltages

are close to 2.5v DC on both Bus Hi and Bus Lo and

considered to be "recessive transmitted logic", while the

Bus + (HI) will climb approximately 1 volt and the Bus -

(LO) will drop approximately 1 volt in the "dominant" state.

In the recessive state there is close to 0 volts

differential, but in the dominant state, the voltage

differential is approximately 2 volts.

The BCM is the Power Mode Master for wake up of HS LAN

modules. If the modules are present on the list when

scanned, but receive no wake up signal, they will not become

active.

If you take the number presented here and do the math, the

measured values support the theory behind how the system

functions.

So, do we need to run off to investigate service information

every time we are faced with a high speed GM LAN failure? It

Depends on our abilities and needs. If we can remember some

rest voltages and peak min max values of up and down 1 volt

for a 2 volt differential, along with what 60 ohms and 120

ohms represent, or anything in between, we may only need to

ustilze information for connector access and the basic LAN

layout, to get our heads around where the LAN may be broken.

You can pretty much guess what the ohm value will be if

modules downstream are lost due to a data line failure.

Regards,

Martin from British Columbia

Vehicle Data

Vehicle Data

65 Replies Received

65 Replies Received

65 Replies Received

65 Replies Received